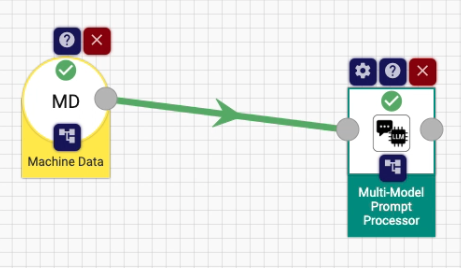

With the introduction of StreamPipes Functions, Apache StreamPipes provides a lightweight way to attach fixed runtime logic to existing streams — without creating a full pipeline element.

Functions are ideal when:

- A full processor would be overkill

- You want logic that runs with the extensions service lifecycle

- You need direct access to incoming events

Previously, functions could maintain in-memory state during runtime, but any restart of the extensions service resulted in a complete state reset.

We now provide a new functionality in developer preview that introduces typed state persistence for Functions, allowing state to survive service restarts.

This allows functions to survive restarts and resume exactly where they stopped.